|

SEMICONDUCTOR ASSEMBLY EQUIPMENTS

|

|

Back Grinding Manual Tape Mounter

Model HTM-08M/12M

This model is a manual type BG (Back Grinding ) tape mounter, for wafer back-grinding, surface protection, for chemical processing, for shipping, and for storage purposes. By using specially tailored cutting tools you can mount wafers with accurately positioned to the Orientation-Flat. It is good for 6", 8" and up to 12" wafer mountings. Various BG tapes can be used.

|

|

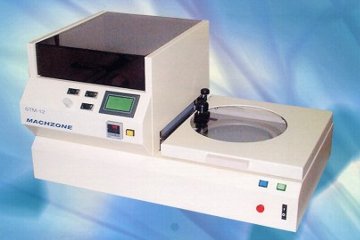

Back Grinding Semi-Automatic Tape Mounter

Model STM-12B

This system provides protecting tape and wafer-tape advancing automatically. It eliminates all of undesired problems during back grinding tape mountings, as it ensures constant roller pressure and film feed speed during adhering motions.

It is good for 6", 8", and up to 12" wafers, various mounting tapes can be used.

|

|

|

|

Back Grinding Semi-Automatic Tape Remover

Model SRM-12B

This system is fro removing BG tape after background without damaing wafers, removing films

accurately in an automatic manner. The speed of peeling depends upon the strength of adhesion.

It can be adjusted to meet desired performances therefore removed of any type tape of BG tapes

and surface protective tapes can be made with the system. It is good for 6,,8, and for 12inch wafers.

|

|

Precut Tape Semi-Automatic Mounter

Model STM-12P/16P

This Semi-Auto equipment is for "circle precut (but rolled)" mounting tape for wafer top surface grinding, chemical etch processing, or surface protection needs. It is done automatically and accurately in a continuous manner. Tape advancing speed, and roller-pressure value setting can be programmed and read by monitor display. It is good for 6", 8", and 12" wafer substrate mountings.

|

|

|

|

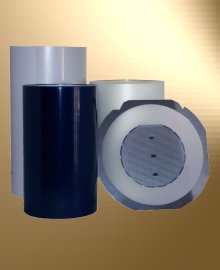

Dicing Tapes

From the most popularly used PVC (Poly Vinyl Chloride) tapes to the strong adhesion UV (Ultra-Violet curing) tapes are handled, not only to the domestic Japanese market but, through overseas.

Standard PVC Tapes Standard PVC Tapes

No Silicon remover is used. The acrylic adhesive in use have longer shelf life.

UV Curable Tapes UV Curable Tapes

Two types of base film to choose, PVC and PO (Poly Olefin). All of such tapes are anti-static electricity treated. The thickness of base film as well as the acrylic adhesive are in a well tightened thickness tolerances therefore, good for cut all the way through dicing and back grind use.

Strong Adhesion UV Tapes Strong Adhesion UV Tapes

Securing substrates firmly during dicing operations, it can achieve optimum result. A Chlorine free soft poly olefin and PVC films are available. You can select your desired adhesion strength.

|

|

|

Manual Tape Mounter

Model HTM-08MD

Linear roller pressure avoids bubble entrap during applying tape onto substrate, it will avoid diced chip fly-off during dicing. This model is good for all types of tapes such as PVC, PO to UV, and hard PET-based tapes. Optional "non-contact chuck table" can be utilized. Circle cutting blade lasts long life, operation safety consideration on open/close covers, designed to meet easy-handling.

|

|

Semi-Automatic Tape Mounter

Model STM-12D

This model features automated its tape advancing and wafer mounting., as more productivity increased. Uniform pressure and speed control of roller made it possible for very thin wafer and bump wafer mountings. Option mounting for non-contact, and rectangular-sized wafers available. Long life, and by using special cutting blade made it possible to handle PVC, UV and hard PET tape cuttings.

|

|

|

|

Wafer Expanding System

Model EXM-06M

This model is to pickup diced devices on tape easier. A frame-mounted wafers (after diced, or after scribed and broke) is expanded to have tape stretched on radial direction to make diced chips easier to pickup from tape.

Percentage of elongation and speed of stretch is programmable, along with the cutting mechanism for stretched discard tapes. The heated stage makes tape soften so that expansion can be made very smoothly.

This unit is compact-sized for table-top use.

|

|

Grip Ring

Plastic double-ring snap-on type, electrically conductive materials in use. MSDS (material safety data sheet) is available.

|

|

|

UV Curing Systems

Model UCM-12M/16M

This system is for reducing adhesive stickiness of UV Tapes by exposing Ultra-Violet light for irradiation, to make diced device pickups easier.

This system uses Black-Light UV lamps, advantages are; long-life of fluorescent light source, inexpensive equipment cost advantage, Ozone-free, replacement light bulbs can be purchased easier, anywhere. The wavelength of 350 to 360 nm, of which has uniform brightness for all types of UV curable films. Nitrogen purge to accelerate hardening UV is standard equipped.

|

|

UV Dry Cleaning System

Model UDM-08M/12M

The cleaning method is to use light energy from the UV lamp, and developed ozone from such energy. Therefore, without giving damage to the materials, but product is cleaned.

This unit is considered as enviromentally clean.

|

|

|

|

|